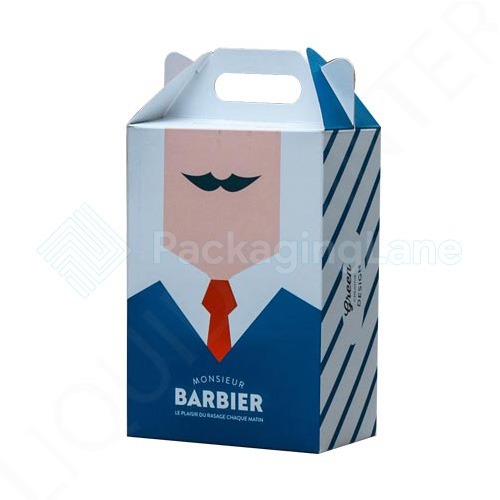

Custom Gable Boxes – Secure, Stylish Packaging Made Simple

Choose custom gable boxes for reliable gift, food, or retail packaging. Each box locks fast with a built-in handle for safe carrying. Select from thickness options up to 24pt cardstock for a sturdy feel.Order sizes start as low as 100 units, and you can select from multiple box sizes to match your product. GMP-compliant materials help keep food fresh while giving a polished retail look.

Materials & Construction

Packaging Lane offers board types including kraft, SBS, and corrugated. Each material supports different branding needs and transit conditions. Corrugated builds more strength for heavy or distant shipments, giving products extra protection.Choose thickness from standard to extra-durable options. This affects box rigidity and how much weight it can manage. For bulk or fragile goods, thick walls hold shape and reduce damage risk.Box samples for custom gable boxes are ready to ship fast. Efficient timelines support tight project schedules and clear launch dates.

Gable Box Structures

Standard gable boxes work well for lightweight retail items. Reinforced designs suit heavier contents and stacking needs. Choose between flat-pack options for bulk shipments or pre-assembled formats to save time on busy packing lines.Select from single-layer or doubled wall panels. Handle styles range from simple cuts to wrapped grips; reinforced handles last longer when you fill each box to its upper weight limit. Each style is ready for quick production.Sizes run from 6x4x4 up to 12x8x8 inches, covering most retail or catering needs. packaging lane lets you create custom gable boxes for special shapes, handle specs, and branded finishes.

Material Selection Tips

For food, choose FDA-approved stocks like white cardboard or kraft. These resist grease and help keep contents fresh, which prevents waste. For retail or gift uses, thicker options like 18pt or 24pt work well and support heavy products.Gloss, matte, or soft-touch finishes change the look and feel. But not all finishes are suitable for foods. Confirm finish compatibility with your product for safe use.Decide based on your product weight, shelf appeal, and desired print quality. Packaging Lane supplies and ships boxes quickly so you can plan launches with less delay.

Custom Print & Finishing Options

Packaging Lane offers multiple print methods, including digital, offset, and flexographic, to match your artwork needs. This allows you to achieve fine gradients, sharp logos, or bold colors for your retail goals.Color matching uses Pantone and CMYK standards for strong brand accuracy. With tight controls, what you see in proofs is what appears on your boxes, supporting consistent shelf presence.Finishing choices include matte or gloss film, spot UV, and soft-touch coatings. All are available for orders as low as 100 pieces. Typical lead time fits a range of launch deadlines for custom gable boxes.

Printing Methods

Digital printing lets you order short runs of 100 units or fewer without setup fees. This method works best for fast changes or small-batch testing, so you save time and money when needs shift quickly.Offset printing fits larger orders starting at 500 units. It produces sharp images with consistent color, which helps your brand stay true from the first box to the last. Pantone printing uses spot colors to match brand tones exactly, making it ideal for custom gable boxes with strict color standards.For any method, expect your printed boxes to ship promptly. This window helps you keep inventory on track and meet tight launch dates.

Finishing Choices

Pick from matte, gloss, or soft-touch coatings to get your exact surface feel. Matte hides fingerprints and gives a muted look, while gloss adds shine and draws attention. Soft-touch gives a smooth, almost velvet feel that stands out in hand.Add impact with spot UV, window cutouts, or foil stamping. Spot UV highlights your logo with shine on a precise area. Window cutouts let customers see the product inside. Foil stamping uses metallic accents for sharp detail.Choose these options for custom gable boxes. All finishing details are ready fast, with standard production completing quickly from Packaging Lane.

Add-On Branding Options

Choose inside printing for messages or patterns that surprise buyers during unboxing. This extra surface can support brand recall and increase perceived value. Inside print area matches exterior sizes up to 12 x 9 x 7 inches.Add ribbons or tags made from satin or kraft paper. Both create a tactile, upscale experience and help products stand out as gifts or specialty items. Ribbons are cut to match box handles and ships attached for accuracy.Branding upgrades add 2 days to standard production, so total turnaround is fast for most orders. Each option fits Packaging Lane custom gable boxes with no change to existing order minimums.

Sizing & Capacity

Packaging Lane builds boxes to fit orders from 4 x 2 x 2 inches up to 24 x 16 x 12 inches. You can choose a size that matches your product, reducing wasted space and lowering shipping costs.These ranges suit items from favors to bulk retail. For accurate fit, measure the length, width, and height of your product. Add a fraction of an inch if padding or inserts are needed.Production is ready quickly, allowing fast fulfillment once you confirm your custom gable boxes size.

Choosing Your Box Size

Measure your product’s height, width, and depth with a ruler or tape before choosing a box. Allow extra space—at least 0.25 to 0.5 inches per side—to prevent crushing or bending during shipping.Check the size charts on Packaging Lane for food, gift, or retail options. Each chart lists specific internal dimensions so you match your items precisely and avoid wasted material or excess shipping costs.Orders for custom gable boxes are produced promptly. This lead time lets you plan ahead and receive packaging that protects and fits your products.

Weight Limits & Packing Tips

Box material sets safe load limits. Corrugated holds up to 25 kg, while standard card supports lighter weights, like up to 5 kg. Packing Lane recommends reviewing specs for each box size before heavy shipments.Overfilling can crush corners or shift items in transit. Fill gaps with kraft paper to avoid folding and keep products snug. For fragile items, double-wall material adds strength and reduces collapse risk.Pack and seal all boxes at least 24 hours before the production window. This step helps avoid last-minute packing issues and keeps your custom gable boxes ready for prompt delivery.

Sustainability & Compliance

Packaging Lane offers eco-materials for every order. Choose recycled board, FSC or SFI-certified paper, and safe water-based inks. These steps help buyers meet regulatory standards and reduce landfill waste.All inks and coatings we use have documented safety data. This means your shipment meets US and EU safety requirements. Safe materials protect products during deliveries.Every order comes with materials that can be easily recycled in standard curbside programs. This supports corporate targets for waste reduction and sustainable business reporting.

Recyclable & Compostable Choices

Packaging Lane uses board grades that meet curbside recyclability standards in the US and EU. You can place boxes in single-stream bins after flattening, which helps speed up local recycling workflows.Some sizes are available with certified compostable linings. These break down in commercial compost within 90-180 days, helping meet waste diversion targets while supporting food-contact safety.Clear disposal icons are printed on all custom gable boxes. This guides end-users to recycle or compost correctly after use. Production lead time is fast.

Ordering, Lead Times & Support

Packaging Lane sets a minimum order of 100 units for custom gable boxes. This helps you manage budget while securing the quantity needed for any campaign or event.Standard production finishes in 10 to 12 days, and shipping and delivery are included in this timeframe. If you need boxes sooner, rush production is available, speeding up delivery.Order plain or printed samples to check size and design before full production. Shipping details are confirmed on order, so you can plan for your launch.

How to Order

Start your order with Packaging Lane by choosing box size, quantity, and material. Upload print-ready artwork files in PDF or AI format for accurate color and sharp detail in production.After artwork uploads, our team sends a digital proof in 24 hours. Review and approve this proof to lock in your design; changes can be requested at this stage۔

Reviews

There are no reviews yet.