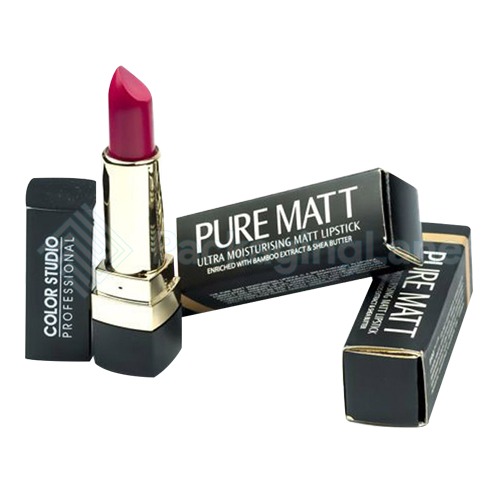

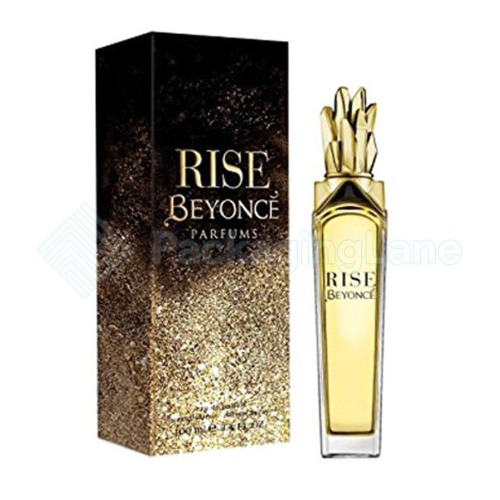

Custom Lipstick Boxes for Unique Branding & Secure Packaging

Packaging Lane custom lipstick boxes keep lipstick safe from impact or heat. Each box is made to fit standard lipstick tubes and can be ordered to match your exact sizes. Choose durable cardstock or rigid board to resist dents and preserve color. Printing options let you add your own graphics and logo, supporting retail shelf impact and brand visibility. No detail gets missed, from precise box fit to sharp, consistent branding.

Materials & Build Quality

Packaging Lane uses cardstocks ranging from 14pt to 24pt, in both white and colored options. Thicker stock helps protect lipstick tubes from bends or dents during shipping. Each box panel fits snug, keeping products secure in storage. Strong adhesives or lock mechanisms stop lids from popping open, cutting down on mishaps in transit. Custom lipstick boxes offer options suited for your brand and timeline.

Material Choices & Protection

Paperboard works for light retail packs. It holds shape for small runs and offers color printing for branded cosmetic displays. Corrugated suits bulk shipment; its layered build cuts breakage in transit for orders of 500 or more. Rigid stock fits high-end launches. Its dense board resists dents and delivers a sharp look, helping luxury shades stand out in stores. All options protect contents but vary in appearance and strength. For eco goals, try recycled board. Each choice can support custom lipstick boxes.

Structural Options

Choose from box shapes like tuck end, sleeve, two-piece, or box with a window. Each offers distinct display and stacking benefits. Many clients select window styles to improve product visibility at retail. Add locks, flaps, or inserts based on your assembly needs. A secure lock reduces the risk of product shifting during shipment. Custom inserts can fit lipsticks from 8mm to 16mm in diameter, helping protect fragile finishes. Tamper-evident tabs or seals signal packaging integrity to end buyers.

Print Methods & Finishing Touches

Choose offset or digital printing to fit your run size. Both support sharp print detail and fast turnaround, with offset suitable for high-volume orders and digital for lower quantities. Pantone color matching keeps brand colors consistent and accurate across every batch. Select finishes like matte, gloss, or soft-touch. Each surface finish changes the look and feel: matte mutes glare, gloss adds shine, and soft-touch feels smooth. Coatings add scratch resistance, helping your boxes look new during shipping.

Color & Artwork Guidelines

Submit artwork in high-resolution formats, such as AI or PDF files. Set bleeds to at least 0.125 inches and keep text inside a safe zone for sharp, accurate prints. Our color proofing process gives you print previews before production. This step helps reduce surprises and mismatches, so shades match your expectations. You will review and approve colors before print.

Premium Effects & Add-Ons

Add foil stamping in gold, rose gold, or silver to make small packaging stand out and attract attention under strong lighting. Spot UV highlights create a raised, glossy effect on selected areas, which makes logos and designs more noticeable for shoppers. Choose embossing for raised text or logos and debossing for pressed-in effects. Both techniques work best on solid or thick custom lipstick boxes between 14pt and 24pt. Transparent windows or custom inserts show off color options and hold each product steady during shipping. Packaging Lane offers these finishes as part of any order. Use these options to help your boxes stand out and impress at retail.

Sizing & Product Fit

Choose from single, duo, or multi-pack lipstick box sizes. Each box fits standard tubes ranging from 11–15mm in diameter and up to 75mm in height, preventing movement and damage during transit. Measure your lipstick tube at the base for diameter and from base to cap for height. Accurate sizing avoids wasted packaging and secures each product snugly within its box. Use standard box sizes for bullet lipsticks, slim tubes, and liquid formats to simplify planning.

Measuring Tips & Guides

Measure your product length, width, and height using millimeters. Add 1-2 mm to each side for a secure fit and easy removal. This prevents crushing during transport. For round, square, or unique shapes, take the largest width and depth. Check all edges and add extra room for odd features like curves or caps. This ensures custom boxes align with real product sizes. Need support? Packaging Lane provides clear templates and diagrams on request. Requesting the right template helps you send accurate specs, reducing possible errors and saving time on your next order.

Inserts & Divider Options

Pick from cardboard, foam, or eco-paper inserts to hold products steady in transit. Each keeps items from shifting or rubbing, reducing breakage and scuffs. Cardboard fits snugly for simple setups; foam works best for odd shapes; eco-paper suits lightweight gifts. Dividers create clear sections inside the box, supporting both neat arrangement and visual appeal. A well-fitted insert also boosts the look of your gift set, making the unboxing feel organized. When ordering custom lipstick boxes from Packaging Lane, match the insert type and shape to your product size and finish.

Sustainability & Compliance

Packaging Lane offers options like recycled cardboard, FSC-certified stock, and glues that biodegrade under standard landfill conditions. These materials help brands shrink their environmental impact while meeting packaging standards for safety and sourcing. Soy and plant-based inks reduce chemical load and give strong colors without harsh solvents. This supports safer handling in production and aligns with beauty industry trends that call for eco-aware packaging. Compliance steps include using the right warning labels and finishings approved for cosmetics.

Recyclability

Most Packaging Lane lipstick boxes use FSC-certified paperboard, supporting responsible sourcing. This gives buyers proof of environmentally managed raw material. Paperboard and cardboard parts are curbside recyclable. Buyers can separate any film liner before recycling to avoid contamination, ensuring the process fits local requirements. Each box can be printed with clear recycling marks. Correct labeling supports easier sorting after use.

Health & Safety Considerations

We use food-grade inks and adhesives proven safe for cosmetics packaging. This helps keep contents uncontaminated, reducing risks for sensitive users. Allergenic materials are disclosed with each order. Buyers know exactly what materials contact their product, supporting clear communication with end consumers. Each box is labeled following industry guidelines for ingredient transparency.

Ordering, Lead Times & Support

Place a minimum order of 100 units to start. For larger volumes, automatic price breaks help you control costs as your needs grow. Sampling and bulk production have clear timelines: samples ship within 4 to 6 days and bulk orders deliver in 10 to 12 days. This schedule lets you plan launches or restocks with less guesswork. Choose between standard and expedited shipping options with full tracking from dispatch. You can see your shipment’s progress at every step until delivery.

Artwork Setup & File Submission

Upload files in PDF, AI, or EPS formats for print-ready results. Files under 100 MB load faster, which speeds up production for your packaging lane order. Ask for custom dielines if your design needs unique folds or shapes. Our team responds within one business day, so design adjustments stay on track. Check your artwork setup for a minimum 3 mm bleed, outlines on all fonts, and CMYK color mode.

Reviews

There are no reviews yet.