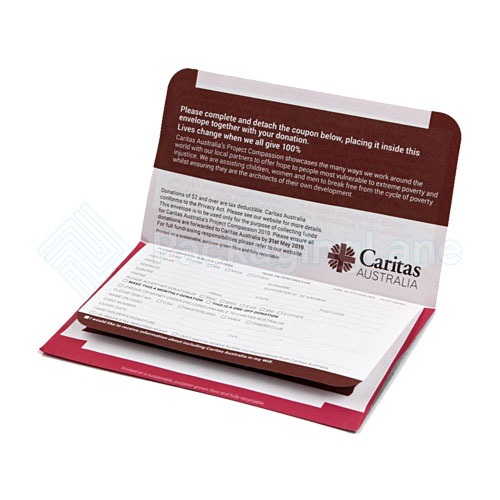

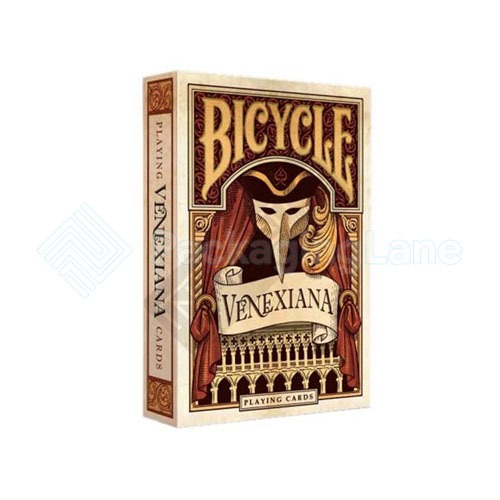

Custom Sleeve Boxes for Branded Product Packaging

Showcase your products in branded Packaging Lane custom sleeve boxes. Each box offers easy slide-open access for retail, ecommerce, or gift use. Choose your box size, print style, and materials to align with your brand. The double-layer structure adds strength, reducing the risk of crushed goods during shipping or shelf display. All printing and finishes are crisp and precise, so your graphics stand out. Sizes start as small as 2 x 2 inches to fit smaller products without wasted space.

Box Materials & Construction

Packaging Lane offers stock choices in kraft, white, coated, and colored boards. Thickness ranges from 14 pt to 24 pt, so you can match rigidity to your product. Select material by product needs: kraft for strength, coated for print quality, or colored for standout shelf appeal. Precise thickness protects items in food, retail, or cosmetics applications. Strong sides prevent crushing during storage and transit. Secure seams reduce product movement for fewer damages.

Material Choices

Kraft sleeves suit brands that want a natural, textured look. White sleeves give a crisp, clean surface for bold colors. Sizes start as small as 2×6 inches, with minimums of 500 units. Choose matte for a soft look that hides fingerprints. Gloss creates shine and makes printed designs pop. Each finish affects how your colors appear under store lights. Both Kraft and white options can meet direct food contact rules if lined. Ask about testing and certifications to meet safety standards.

Box Durability Features

Packaging Lane boxes meet shipping strength ratings, with tested resistance to heavy stacking and handling. This prevents box failure in transit and keeps products intact for arrival. Each box is qualified for storage loads up to 25 kg. Moisture-resistant coatings hold up in humid warehouses or during short-term outdoor exposure. Surfaces also repel scuffs and abrasions, so branding and labeling stay clear through transit. Custom sleeve boxes maintain shape and structural integrity after repeated handling.

Print Methods & Finishing Options

Choose offset, digital, or Pantone print for accurate design reproduction. Offset suits large runs, digital works best for small-batch flexibility, and Pantone ensures color precision. Finishes like matte, gloss, soft-touch, and UV add a specific look and feel. Matte limits glare, gloss boosts color depth, and soft-touch coats the surface for a velvety effect. Branding add-ons include foil, emboss, and deboss options. These features create raised, recessed, or metallic details for immediate shelf impact.

Print Quality & Color Accuracy

Set up your print files with 0.125-inch bleeds and clear safe zones to avoid trimmed edges. This keeps artwork and text crisp on every box. Choose Pantone colors when color consistency is a must. Spot matching ensures your brand shades look the same on every order, reducing the risk of off-shade prints.

After the file upload, Packaging Lane will send a digital proof for approval.

Special Branding Effects

Foil stamping, spot UV, and emboss or deboss add shine, texture, or depth that buyers notice fast. These options fit both inside and outside print, letting you highlight logos or patterns where they matter most. For example, spot UV draws the eye to brand names while embossing delivers a raised touch point for instant quality cues. Adding these effects increases unit cost by 10% to 20%. Finishing steps also extend lead times. Use special branding on custom sleeve boxes to mark limited editions or drive shelf appeal. Inside print works for messaging or loyalty codes, staying protected until the box opens.

Sizing & Custom Fit

Packaging Lane offers custom size ranges so your products get a snug fit. You can select widths and lengths to match your item dimensions, reducing the risk of movement during shipping. To check for a precise sleeve fit, measure your product’s length, width, and height with a ruler or caliper. Accurate measurements help avoid wasted space and material. Order sleeves with or without internal trays, based on your protection needs.

Measuring & Ordering the Right Size

Start by measuring the item’s width, depth, and sleeve length with a ruler. Add 1/16 inch to each side for a secure but not tight fit. For example, if your product is 3 inches wide, order at least 3-1/16 inches in sleeve width. Avoid common mistakes like measuring only one dimension or skipping the depth. Always measure from the largest points of your item to prevent crumpled corners. Packaging Lane offers custom sleeve boxes in widths from 1 inch up to 20 inches and depths from 0.5 inch to 8 inches.

Accessories & Inserts

Foam, cardboard, and molded trays keep products in place during transit and on shelves. This prevents damage and keeps contents steady, even for delicate or odd-shaped goods. Add display windows or handles to make boxes easier to carry or showcase. These options help highlight the contents and give buyers a better grip, reducing drops and improving shelf appeal. Inserts are sized to match your requirements.

Regulatory Compliance

Packaging Lane meets food and cosmetic contact-safety by using certified inks and materials. This helps you pass audit checks and protects your brand from recalls. State and country rules change. Your order comes with labeling that matches regional law, which lowers risk at customs or the point of sale. Every shipment arrives with full documentation. Keep these records ready for audits or to match compliance notes, making inspection fast and stress-free.

Artwork & Dieline Setup

Upload artwork files in PDF, AI, or EPS format for clear prints. These files keep lines crisp, which prevents production delays for Packaging Lane orders. Need a custom dieline? Request one for your box size, and Packaging Lane returns it within 24 hours. Accurate dielines avoid costly fit issues later.

Before submitting, check print resolution (300 DPI or higher) and convert all fonts to outlines. Following this checklist helps your custom sleeve boxes ship without edits.

Production & Delivery Timeframes

We start your order with a digital proof, so you can confirm details before production begins. This step reduces errors and helps your custom sleeve boxes arrive as expected. Once you approve the proof, production takes place within 10 to 12 days. This window allows for quality checks at each stage. After production, shipping times depend on your choice. Standard orders usually arrive within the listed timeframe, while expedited shipping offers a faster option for urgent needs.

Reviews

There are no reviews yet.