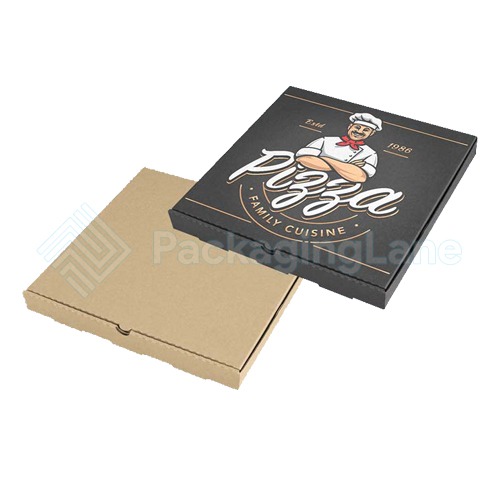

Custom Pizza Boxes for Hot, Fresh Delivery

Packaging Lane provides boxes that fit 10″ to 18″ pizzas, keeping pies secure during delivery and carryout. Each box uses food-grade corrugated board, so your pizza stays fresh and resists grease stains. Boxes arrive flat for easy stacking and quick assembly. Trusted by local pizzerias to meet tight, real-world timelines. Reliable, vented construction lets steam escape, preventing soggy crusts and helping your pizza reach customers in a presentable condition.

Materials & Build

Select from white, kraft, or specialty board grades based on your pizza style and visual needs. Strong boards prevent warping and hold up to stack weights in busy kitchens or high-volume delivery. Food-safe coatings keep contents fresh and guard against grease stains. Each box meets safety standards for direct food contact, giving peace of mind with every use. Packaging Lane maintains speed without missing on box strength or finish options.

Corrugated vs. Solid Board

The corrugated board uses a fluted middle layer for added strength and shock absorption. This protects food during shipment, making it an effective choice for larger orders or custom pizza boxes. Each size supports different weight ranges. The solid board is thinner and offers less insulation, but gives a clean print surface. Choose this for smaller, lightweight boxes when visual impact matters more than heavy-duty protection. Corrugated options cost more due to materials and shipping weight, but lower the risk of product damage. A solid board is more budget-friendly for simple, small-volume needs.

Grease-Resistant Linings

Packaging Lane offers linings in several grades that protect food from leaks and sogginess. Barrier coatings block oil, so the box stays strong even with heavy or loaded pizzas. This prevents collapse and keeps tables mess-free. Choose between waxed, poly-coated, or specialty FDA-approved papers. Each is checked to meet food safety rules so the packaging suits both delivery and dine-in. Buyers can select the lining type best for their menu and moisture level. Standard production for custom pizza boxes with these linings lets you plan rollouts with confidence and hit tight schedules.

Perforations and Vents

Air vents and precision perforations let hot air and steam escape from your pizza packaging. This reduces moisture, so the crust stays firm and slices do not get soggy after transit. Packaging Lane uses machine-punched holes with tight tolerances to balance airflow and keep temperature loss within predictable ranges. We adjust the number and size of vents for different pizza box sizes. Quick lead time helps you switch sizes or vent layouts as your operation needs change.

Print & Branding

Choose from full-color CMYK printing for bold designs or single-color printing for a simple look. Both options keep colors consistent across orders. Logo placement is precise on every box, helping customers spot your brand immediately. Print area supports sharp edges and clean visibility, even for small graphics. Branding stands out with your custom design on the pizza boxes, so your packaging stays on schedule.

Print Methods & Color Options

Packaging Lane supports flexo, digital, and offset printing for orders. Flexo suits large runs and gives consistent results. Digital offers sharp detail for short batches under 500 units. Offset handles mid to high volumes with balanced color output. Pantone color matching is available for precise brand consistency. Provide your code, and your exact shade appears on every box, reducing color variance across orders. Submit high-resolution artwork files in PDF or AI format for best results. Clear files prevent misprints and speed up approval. Typical turnaround for new custom pizza boxes is fast.

Finishes & Protective Coatings

Choose matte or gloss finishes to match your brand image and give each box a tactile surface. Both finishes protect against scuffs during transit, keeping boxes looking new when customers open their orders. All coatings meet food-contact safety standards in the U.S., so boxes stay compliant. Boxes arrive ready for use, no extra handling steps needed. Packaging Lane prepares every batch for easy stacking and storage, so you save time unpacking.

Window & Cutout Features

Add a window when you want buyers to see the pizza before opening the box. Clear film options balance product visibility with protection from dust or handling. The film material is designed to withstand a range of oven temperatures, so food quality stays high in transit. Cutouts help show off your product but can allow heat to escape. Choose the placement and size based on your need for freshness versus the need to display. Film-covered windows, usually in 2 x 4 or 3 x 6 inch sizes, offer a middle ground for most uses. Order changes to window or cutout size do not affect the timeline unless specialty films are required.

Sizing & Fit

Box options span pizza diameters from 8 to 20 inches. This lets you pick the right size for anything from personal to family pies. Select box heights for thin or thick crust. Taller options keep deep-dish pizzas intact. Shorter sizes suit flat, traditional styles. Boxes from Packaging Lane stack well, so you save space in transit or storage.

Standard Pizza Box Sizes

Pizza boxes come in standard sizes based on pizza diameter. Common options include 10-inch for small, 12-inch for medium, 14-inch for large, and 16-inch for extra large pizzas. This range helps you match each box to the pie, reducing waste and keeping pizzas secure. Choose box sizes by pizza type. Square-cut Sicilian or thick-crust pies may need extra depth or a slightly larger box, while thin-crust pizzas fit best in standard height boxes. Correct sizing keeps each style fresh and presentable for delivery or pickup. You can also order custom pizza boxes to fit nonstandard sizes or shapes, helping streamline kitchen operations and improve the customer experience.

Custom Sizing for Unique Orders

Measure each side carefully if your order is a deep-dish or a non-standard rectangle. For boxes over 20 inches or with extra height, specify exact length, width, and depth in inches to get a precise fit. Custom sizes help protect pizzas in transit and prevent shifting. Submit your custom dimensions directly to Packaging Lane when you request a quote. Our team confirms your specs and provides clear guidelines so your boxes match your actual pizza measurements. You get a snug, secure fit with every order.

Fit Tips: Avoiding Warping & Crush

Choose boxes with side walls no less than 1.75 inches thick. Sturdy materials help keep pizzas flat and stop edges from curling during transport. This guards against sauce leaks and dry crusts. Stack no more than three boxes at a time when preparing orders for delivery. Exceeding this can crush pizzas in the bottom layers or cause uneven pressure, risking both shape and toppings. Packaging Lane allows you to plan for peak times. That lead time gives you time to adjust your sizing or quantity if your menu changes before the custom pizza boxes arrive.

Eco-Friendly Material Choices

Packaging Lane offers materials like recycled cardboard, kraft paper, and biodegradable corrugate. Each material option can be recycled or naturally breaks down, reducing landfill waste and streamlining disposal for your customers. Buyers can choose between recyclable or compostable options based on end-of-use goals. For example, Kraft and most cardboard can go in curbside recycling, while compostable options break down fully in commercial compost facilities.

Clear disposal symbols printed on the boxes guide users at the end of life. Ready-to-ship custom pizza boxes fit well with standard product launch schedules.

Waste Reduction & Practical Disposal

Our boxes use materials that are easy to flatten for compact disposal. This cuts landfill space and supports recycling routines for most local programs. Clear disposal steps come printed inside each box. Tear along the seam, flatten, and add to curbside recycling. This saves time for staff and streamlines end-of-day cleanup. Choosing eco-friendly stock in your custom pizza boxes supports less waste from start to finish. Packaging Lane’s sizing fits typical waste bins, so disposal is smooth after busy shifts.

Order Steps: From Design to Doorstep

Send your artwork file to Packaging Lane as your first step. Accepted formats include high-resolution PDF and AI files, so your design prints sharp and accurate. Once your file is received, our team reviews and sends you a digital proof within one business day. Approve the proof to confirm colors, placement, and sizing meet your needs.

Production & Delivery Timeframes

Packaging Lane ships most orders in 10 to 12 days. Buyers can track production timelines to plan for store launches or busy events. Choose between parcel shipping for small runs and freight delivery for bulk orders. Parcel reduces wait for samples; freight keeps costs down on high-volume deliveries. Custom pizza boxes arrive in sturdy cartons to prevent damage during transit. Each shipment method supports order size and protects your packaging investment.

Sample Orders & Reordering

Order a sample box to confirm material and print quality before full production. This lets you see color accuracy and box strength first-hand before a larger commitment. Fast reordering is simple—repeat past sizes, designs, or materials with a single approval. For events or seasonal menus, approve a box run ahead of time to avoid rush costs.

Add-Ons & Accessories

Choose from handles, inserts, and pizza savers sized to fit every box. These keep pizzas stable and make carryout safer, so your food arrives as planned. Each accessory fits custom dimensions for better stacking and handling at your shop. Add your logo with custom labels or pair marketing inserts with your packaging. Clear messaging builds recall for repeat orders and makes information stand out on delivery. All print options work on stock or custom pizza boxes from Packaging Lane.

Pizza Savers & Inserts

Add savers when stacking multiple pizzas or for deliveries over 5 miles to stop cheese and toppings from sticking to the box lid. Options include classic plastic tripods—standard height is 1.5 inches—and cardboard inserts for extra base support. Choose inserts sized from 10 to 18 inches to match your box dimensions. Inserts keep slices in place during transport, giving your pizza a neater look on arrival.

Custom Labels & Stickers

Highlight specials or display key instructions with stickers sized to fit your packaging. Choose from options like waterproof or tamper-evident finishes to fit your needs. Tamper-evident seals protect your goods in transit and build trust with your buyers. Label materials include paper and film, each designed to prevent damage during delivery.

Reviews

There are no reviews yet.