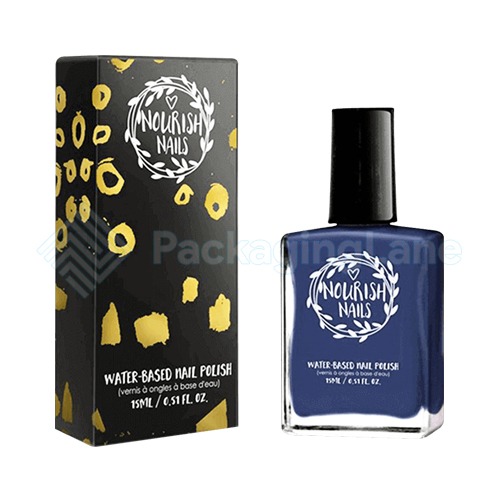

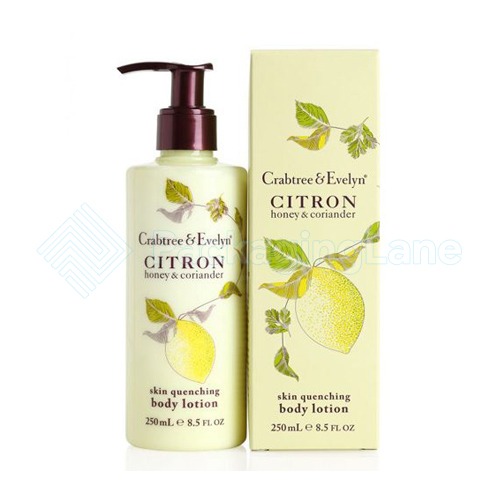

Custom Makeup Boxes: Design, Protect & Present Your Brand

Packaging Lane offers boxes made for cosmetics in rigid, cardboard, or corrugated material. Each style shields fragile items from shipping damage and supports shapes, from palettes to bottles, to fit your product without wasted space. Surface finishes like matte, gloss, or textured lamination show your brand clearly at first touch. Custom cuts and print let colors and details stand out during unboxing. Dimensions run from 2×2 inches to 12×10 inches, letting you match both travel and full-size SKUs. Quality checks spot inconsistent cuts or graphics before boxes leave the plant.

Material & Build Options

Choose from paperboard, corrugated, or rigid board for your packaging. Paperboard works well for single compact cases, while corrugated delivers extra strength for shipping multiple items. Rigid options support heavy palettes or glass bottles, helping limit damage in transit. Thickness can be adjusted between 14pt and 32pt for paperboard, or up to 3mm for rigid builds. Thicker boards add structure, reducing the risk of crushed corners or cracked compacts during shipping. Every box is engineered to balance strength and appearance for makeup products.

Surface Choices (Matte, Gloss, Soft Touch)

Choose from matte, gloss, or soft touch finishes for control over look and feel. Matte reduces glare and resists fingerprints, helping maintain a clean style under shelf lights. Gloss creates a high-shine effect that brings out colors and can hide small scuffs for fast-moving makeup lines. Soft touch adds a velvet feel and shields surfaces from minor scratches. This finish works well for luxury or skincare brands needing tactile impact. All surfaces are available on orders starting at 500 units. Each finish supports your makeup line style by defining how color, detail, and brand presence show on custom makeup boxes. Match your finish to your target market for stronger shelf appeal.

Box Shapes & Closing Styles

Packaging Lane offers boxes in shapes like folding cartons and drawer-style pull-outs. Each shape suits a different makeup product and display need. Sizes range from small (1x1x3 inches) to large (up to 10x12x4 inches). Closures include magnetic lids and locking tabs. Magnetic closures keep high-value items secure, while locking tabs work for quick assembly and bulk shipments. Both types help products arrive intact. Custom makeup boxes can be sized and shaped for new product lines.

Print & Custom Branding Features

Pick from digital, offset, or UV print methods for colors and detail that show true on every order. Our Pantone and CMYK matching supports consistent brand presentation across repeat runs. Finishes like foil, emboss, and spot UV add sharp visual texture that buyers can touch and see up close. Choose custom logo placement on every box to match your sales flow.

Color & Detail Proofing

File setup starts with clear specs. Submit artwork matched to print sizes and formats. Proper setup avoids delays and lets us check fine details early. You choose digital or physical proofs. Digital proofs send quick color checks for approval. Physical proofs add accuracy, so colors on your custom makeup boxes match expectations. Artwork steps include close review and approval before production. We review color profiles, layers, and print tolerances.

Special Effects & Add-Ons

Choose holographic, metallic foil, deboss, or window cutouts to create a strong first impression. Each effect highlights detail, like metallic foil for shine or window cutouts for product previews—so buyers see value at a glance. Specialty finishes are available in various sizes to match your box dimensions. Most add-ons fit boxes from 2×2 up to 7×9 inches. Materials handle standard makeup weights without warping or tearing.

Sizing & Product Fit

Packaging Lane offers fully custom size ranges, so you can match dimensions to your makeup compacts or lipsticks. Share your product measurements—height, width, and depth. We produce boxes that hold items tight, which cuts shipping damage and keeps contents secure. To get the best fit, measure each cosmetic at its widest point using a ruler or caliper. Add 2-3 mm to each side for easy insertion. This detail reduces returns and gives your customers a neat unboxing. Common makeup box sizes start at 2 x 2 x 2 inches and go up to 8 x 6 x 2 inches

Inserts & Internal Protection

Foam, paperboard, and molded pulp inserts protect products during shipping or on shelves. Choose between 1/8-inch foam or rigid paperboard for delicate items, or molded pulp for eco-focused brands. Each option reduces breakage rates by blocking movement. Custom shapes anchor products inside boxes to prevent scuffing or shifting. Sizing fits most retail products from 2 inches to 12 inches, with tolerances as tight as +/- 1 millimeter. Clients often pair these inserts with custom makeup boxes for presentation and secure delivery. Packaging Lane produces inserts in small or large quantities. Ask about reusable or recyclable material options based on your brand’s sustainability goals.

Size Templates & Dielines

Request a template from Packaging Lane in your ideal box size. We offer ready dielines for rounds, rectangles, and common makeup shapes. A precise dieline helps you avoid sizing errors and speeds up approval. Provide your print file as a vector PDF with a 3 mm bleed set. This ensures sharp edges and meets print shop standards. Files following these specs go straight to production without costly delays.

Eco-Friendly Materials

Packaging Lane uses recyclable stock, compostable papers, and soy-based inks. These materials break down faster and leave less waste, helping brands meet eco goals. Select FSC-certified boards or ask for green seals. These prove raw sources are managed responsibly and that your boxes follow strict sustainability guidelines.

Recycling & Disposal Guidance

Most Packaging Lane boxes use easily recycled cardboard. To recycle, remove labels and flatten each box. Place the material in your curbside bin if local guidelines accept it. For clear disposal communication, describe the materials and steps on every shipment receipt. This gives buyers confidence about the safe disposal of their custom makeup boxes. If compostable or specialty coatings are used, indicate this directly on the packaging. Buyers can then sort these boxes separately, reducing landfill and meeting sustainability goals.

Compliance for Cosmetics Packaging

Leave space for full ingredient lists and batch codes when planning your print layout. Buyers gain faster approval, as many regions reject packaging missing these details. Collect supplier documentation for inks, glues, and board, since regulations may require proof before orders ship. Clear records help avoid costly delays if authorities do a spot check. Check rules for your region before confirming your artwork for custom makeup boxes.

Ordering, Lead Times & Support:

- Order starts at a minimum of 100 units. For custom specs or branding, sample making is available so you can check the fit and quality before full production.

- Lead time for production and shipping is 10 to 12 days, and you can request a rush service if you have tight deadlines, helping you launch or restock faster.

- Packaging Lane provides updates at each step so you always know when your custom makeup boxes will be ready.

- You get clear timelines so you can plan your launch without last-minute stress and stay prepared for product releases or restocks.

- All surfaces are available on orders starting at 500 units.

Quote & Artwork Submission Steps

Start your order for custom makeup boxes by submitting size, quantity, and material needs online. You receive a clear price quote fast, so you can finalize budgets without delay. Send your artwork in PDF or AI format. For the best print quality, files should be at least 300 dpi. The Packaging Lane team reviews each file and lets you know if anything needs adjusting. After you approve the final proof, production begins, and the order is delivered to your doorstep.

Quality Checks & Tolerance Expectations

Print and trim tolerances stay within a ±1 mm range. This keeps branding and design elements clearly placed, so your visual expectations match the final product. Each order receives a sample evaluation. Physical samples let you check size, color, and finish before full production—reducing surprises and wasted material. Final sign-off follows clear checkpoints. Production begins after your approval, leading to reliable results.

Reviews

There are no reviews yet.