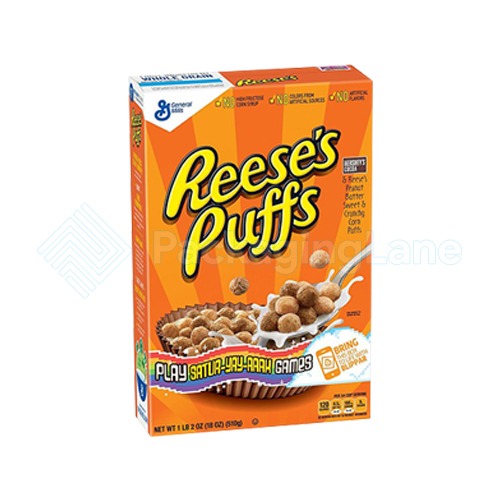

Custom Cereal Boxes, Stand Out on Store Shelves

Packaging Lane delivers custom-printed cereal boxes in your selected sizes for cereal makers, stores, and co-packers. Cardboard grades and dimensions meet warehouse and shelf needs, helping your product face forward and align with display standards. Imprint high-color graphics and brand elements to draw eyes at the point of sale. Variable box sizes and secure closures support safe transit without shifting or crushing. This means each unit protects freshness and reduces damaged returns.

Materials & Box Construction

Choose from multiple cardboard and paperboard grades, including thicknesses from 12pt to 24pt. Thicker stock gives more crush resistance, so your boxes arrive intact even after shipping. Lighter grades fit lighter cereals or lower shipping costs. Food-safe coatings stop moisture and oil absorption. Your product stays fresh, so it is ready for customers on the shelf. All coatings meet FDA standards for direct food contact. Tight seams and snap-shut closures prevent product leaks during transit.

Paperboard Types & Thicknesses

Choose from paperboard thicknesses in the 16–24 pt range. Thicker paperboard adds strength, making it good for heavier food products that need extra protection during shipping. White paperboard gives Custom Cereal Boxes a smooth surface for sharp, vibrant prints. Kraft paperboard has a natural look and handles moisture better, which helps keep food fresher. Let Packaging Lane know your sizing and finish early to meet your timeline.

Protection & Freshness Features

Packaging Lane uses barrier layers and linings to help keep food dry. These layers block moisture so cereal stays crisp during shipping and on the shelf. Each box is built to prevent outside air and contaminants from seeping in. That keeps your product free from dust or odors until the end user opens it.

Print & Finishing Choices

Select from offset or digital printing for crisp detail and accurate color on every order. Offset suits high-volume runs, while digital works well for quick changes or small batches. Finish with gloss, matte, or soft-touch coatings to match your shelf needs. Gloss gives extra shine for standout appeal, matte cuts glare for a subtle look, and soft-touch adds a smooth feel that invites handling. Packaging Lane prints to food safety standards for peace of mind.

Print Methods & Color Output

Packaging Lane prints using both CMYK and Pantone color systems. You can match bright brand colors or choose smooth gradients. This gives visual consistency on custom cereal boxes even with repeat orders. For fast setup, submit artwork as high-resolution PDF or AI files. Keep text at least 4mm from trim lines to avoid cutting issues. File guidelines reduce proofing delays and keep print sharpness reliable. Proofs are sent within 2 days for buyer approval. Confirm details before bulk printing to avoid costly fixes.

Branding Finishes & Enhancements

Foil stamping adds a metallic shine to specific areas, helping your box catch the eye on busy retail shelves. Choose silver or gold foil for logos or accents; the contrast boosts perceived value and supports fast product recognition. Embossing raises elements like brand names by up to 1.5 mm, creating a tactile difference shoppers feel in hand. Spot UV applies a glossy layer only where desired, such as to graphics or text, bringing out key features by reflecting light. Window cutouts, custom-shaped up to 3×4 inches, display the product inside and foster trust.

Sizing & Custom Shape Options

Choose from a range of box sizes and shapes to fit your product’s needs. Boxes can be made to standard cereal box dimensions, like 7.75 x 1.8 x 12.25 inches, or customized for unique shapes. Measure your product’s width, depth, and height before ordering. This helps avoid oversized packaging and cuts down on filler material, which lowers shipping costs.

Dielines & File Setup

Send files in AI or PDF. These formats keep layers intact and make edits faster on Packaging Lane’s side. Files must be under 100 MB for upload. Add a 0.125 inch bleed on every edge. Mark fold lines clearly. Accurate bleed and fold guides stop white borders on custom cereal boxes after cutting. Need a dieline? Email your size and style details. Dieline templates are sent within 24 hours, helping you meet shipment windows.

Box Inserts & Accessories

Choose divider options to keep each flavor or portion separated and protected during shipping. Divider widths start at 2 mm, fitting various box sizes and preventing product mix. Add coupons, toys, or other promotional items with inserts sized down to 3×3 cm. This lets you increase value for every box without extra packing steps. Accessory templates are available so you can upload designs directly for precision fits.

Sustainability & Food Compliance

Packaging Lane uses recyclable and compostable materials, so your packaging meets your eco goals and appeals to conscious buyers. Boxes can be produced in sizes ranging from single-serve to family packs, using substrates that fit standard recycling streams. Every order meets FDA and food safety standards. This certification covers inks and coatings, so food stays uncontaminated from surface contact.

Ordering, Lead Times & Support

Packaging Lane sets a minimum order quantity of 100 units for custom cereal boxes. This helps you plan your inventory with clear volume expectations. Request a quote, review your digital proof, and give approval to start production. These simple steps keep your order accurate and reduce errors before any box is made. Production and shipping take 10 to 12 days after approval. You get consistent timelines to plan your launches or restocks.

Sample Orders & Bulk Pricing

Order a sample box to check print quality, box material, and fit for your product. Bulk orders come with tiered discounts based on quantity. The higher your volume, the lower your cost per unit. This model supports repeat runs and helps control your packaging budget. We require an initial payment for samples and a milestone approval before your full run starts. This clear process keeps production on track so you hit your deadlines.

Quality Control & Tolerances

Every order from Packaging Lane meets set print color and cut tolerances. Color variance stays within ±5%, and die-cuts are accurate to ±1.5 mm. This keeps branding consistent across all custom cereal boxes. Each job goes through a checklist before sign-off. Final approval covers artwork, cut lines, and material thickness, ensuring buyers know exactly what they will get. If you find a defect, submit a claim with photos within 3 days of delivery. Most resolutions, including reprints or credits.

Reviews

There are no reviews yet.